homemade injection molding machine part 2

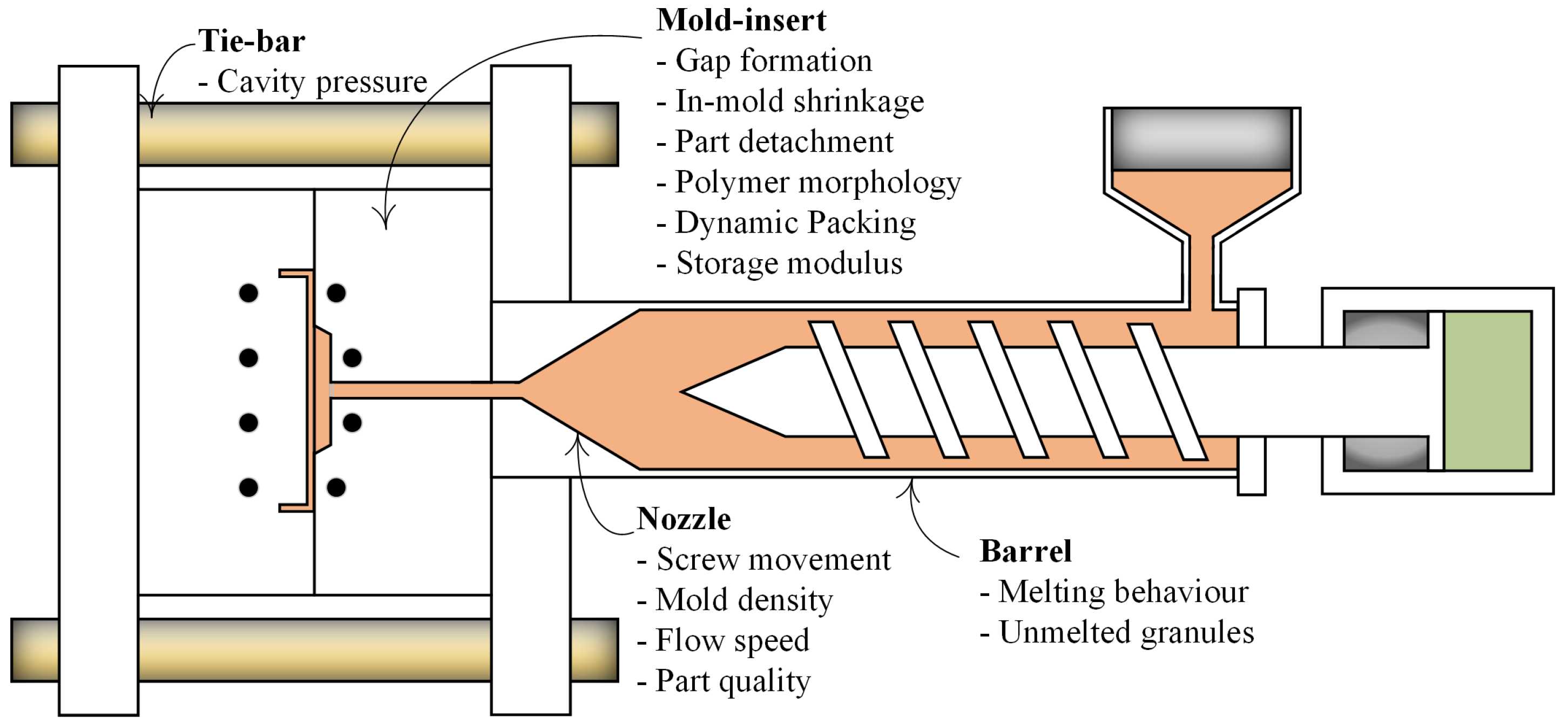

Injection pressure is 100-150 MPa. A bit of his.

Home Plastic Injection Molding With An Epoxy Mold 7 Steps With Pictures Instructables

Injection Molding2 Injection Molding ECONOMICS Injection molding machine is expensive.

. Typical side-action cam design is shown in Figure 14b. You probably came here by way of my YouTube channel. DIY Injection Molding Step by Step 1.

Locking force is 01 to 80 MN. Well use the open-source Blender but the workflow should be fairly similar in any other CAD software. Read on to see the best DIY and desktop injection molding machines.

N total number of parts n number of parts molded in one shot t cycle time Production Cost part Material Cost Mold CostN Molding Machine Cost hrtn 3. Or by machining a desired cavity into an aluminum. The FM3312 and FM3332 Fieldbus Modules in a sturdy metal housing are suitable for temperature measurement on injection molds or on injection barrels.

Operational reliability is additionally ensured by reverse polarity protection against phase voltage. As I build new machines Ill be adding plans here and videos here first maybe extras just for Patreons too or if you just want to join to show your support then Ill very much appreciate it. Mold itself is expensive - Need mass production to justify these costs.

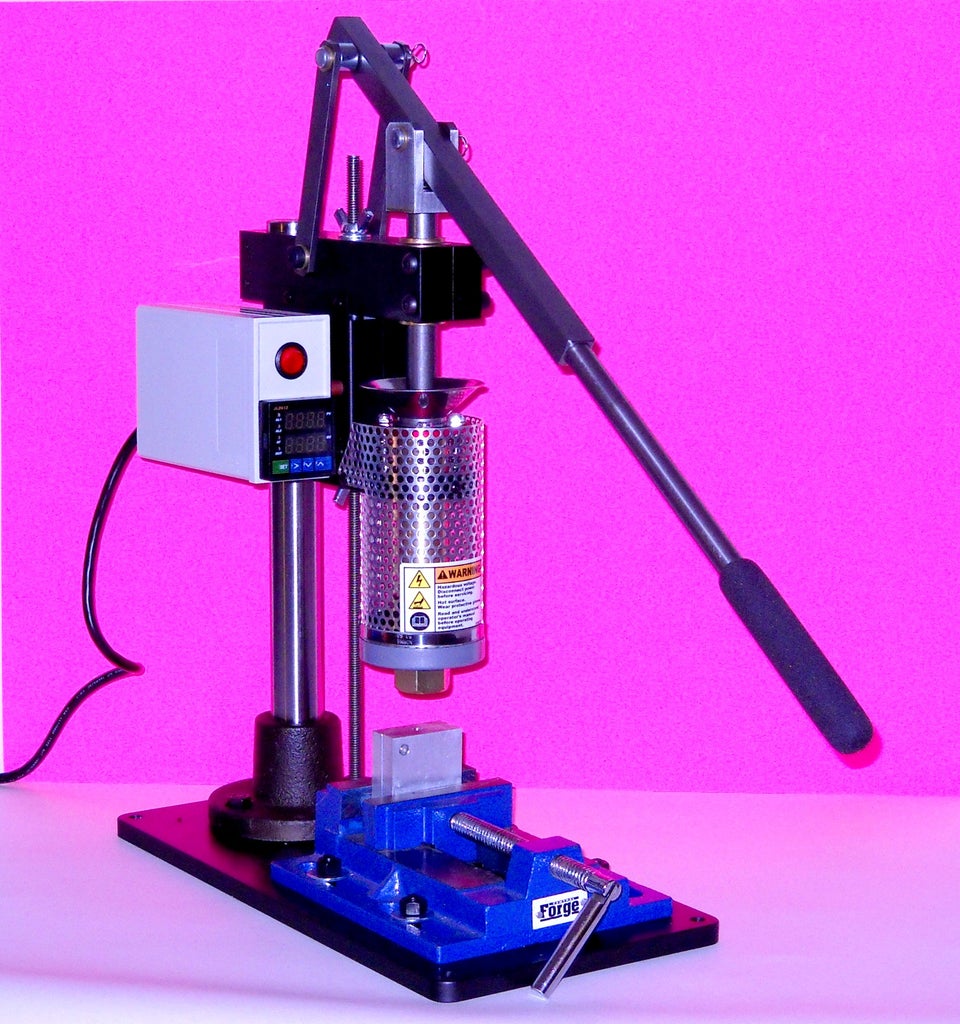

C Clamp the mold in place by turning the vise handle clockwise. We will use epoxy to create our mold. About three years ago he got the itch to build the mini-molder after learning about the Mold-A-Rama machine a blow-molding vending machine that was popular a half century ago.

Heating the mold to just below the plastics melting temperature is highly recommended. Download the blank mold insert design filesyoull use them to create your injection mold design. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle.

LNS Technologies Model 150A. First pick the CAD software tool of your preference to design the mold insert. Figure 14a shows a more complex mold with four side action cams.

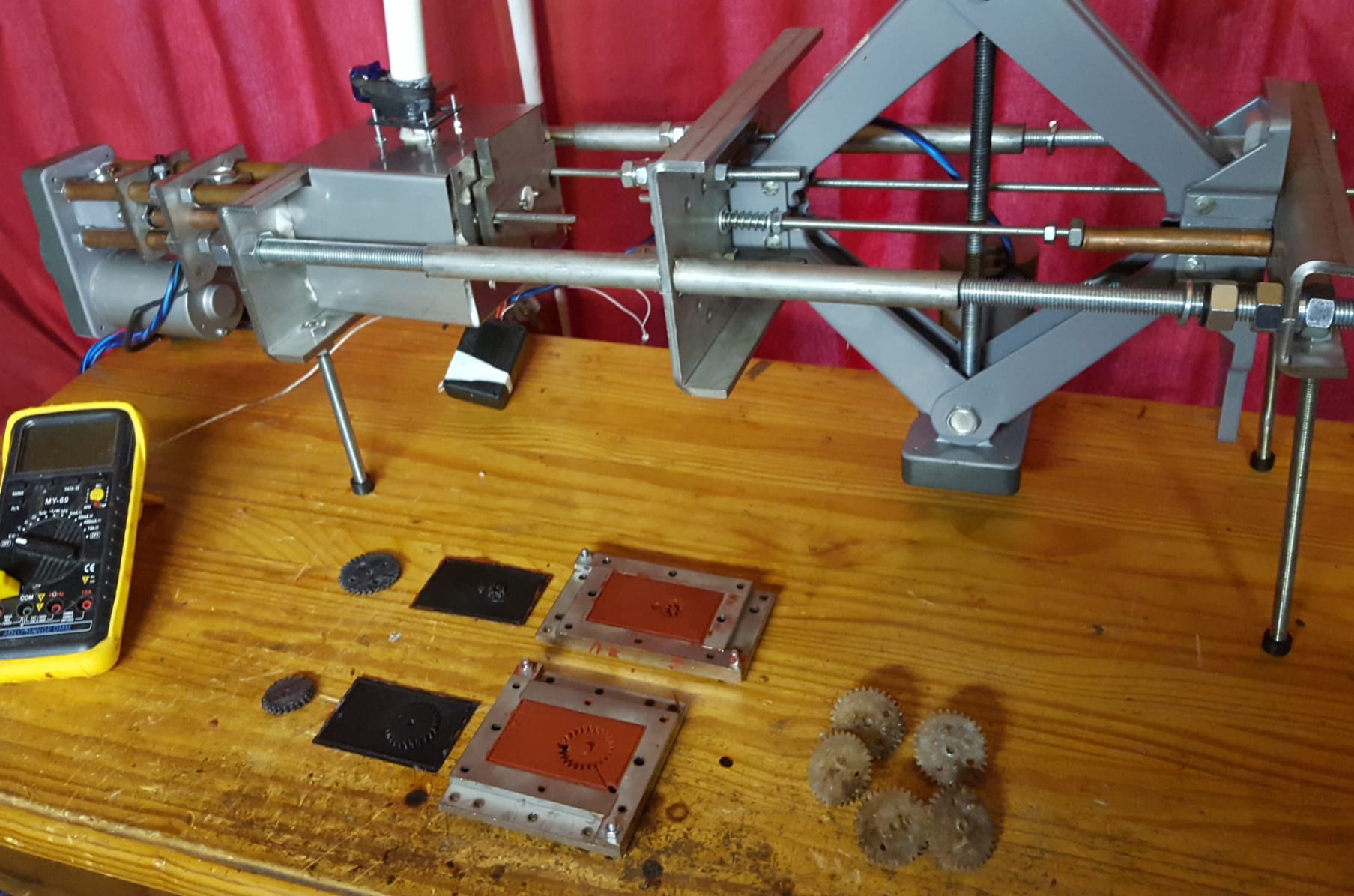

It then solidifies and hardens. -Andy AndysMachines By becoming a patron youll instantly unlock access to 14 exclusive posts. Building the injection stageConstructing the injection barrel piston and nozzle some pneumatics and first test of the machine moulding a small simp.

Design the Mold in CAD. Up to 32 temperature channels can be contained in one industrial connector. The designs can also be easily.

A Place a mold in the machine. It is initially in liquid form but it can then be poured into a mold or frame. Inexpensive homemade molds can be made using an epoxy or urethane resin.

Cycle time for produce a single part is generally 5 to 60 seconds depends upon the parts manufacture. Well admit to being impressed many EDM builds. The top red part is connected with the bolt on top to the moving platen.

Epoxy is actually a two-part liquid. Heating temperature of molding material is 150-350 degree centigrade. The figure below shows the steps of the mold opening.

One method to mold this part is by the use of a core. You need to get a frame in which you can pour the epoxy to make your molds. Injection capacity of molding machine is 12000 to 22106 mm3.

Even pro shops will usually toss the initial few cycles as the machine warms up to operating temperatures. Part 2 continues with refinements that led very quickly to the first useful parts machined quickly and cleanly from thin stock using a custom tool. The first step in our injection molding setup is to create a mold.

Go From 3d Printing To Desktop Injection Moulding Indiegogo

Pin By Arbi Oussama On Car Lights Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

Plastic Injection Moulding Machine Model 4 Youtube

Homemade Injection Molding Machine Homemadetools Net

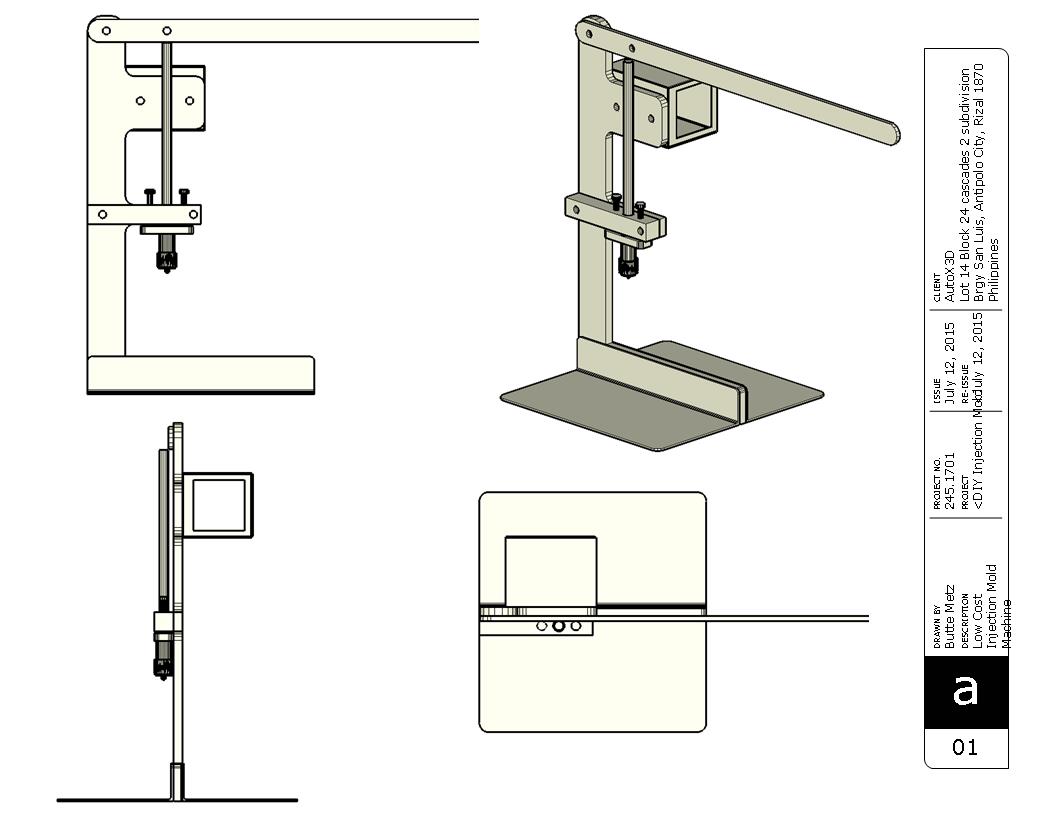

Diy All Electric Plastic Injection Molding Machine 3d Cad Model Library Grabcad

Full Automatic Homemade Injection Molding Machine

Injection Molding Operation An Overview Sciencedirect Topics

Homemade Injection Molding Machine Part 1 Youtube

Plastic Injection Molding Machine Homemadetools Net

Diy Of Small Pneumatic Desktop Injection Mold Machine Youtube

Make Your Own Injection Molding Machine Make

Build Your Own Desktop Injection Molding Machine Youtube

Sensors Free Full Text Ultrasound Sensors For Process Monitoring In Injection Moulding Html

Homemade Plastic Injection Machine Faster Than 3d Printing Youtube

Diy Plastic Injection Molding Machine Test Youtube

Injection Molding How To Set Barrel Zone Temps Plastics Technology

Diy Injection Molding How To Do Injection Molding In House

Home Plastic Injection Molding With An Epoxy Mold 7 Steps With Pictures Instructables